Annette Siegle, PERFECT VAN

An add-on pool for motorhomes, that was the plan. But what good is even the best idea if there is no one available to make it a reality? With Hopf, I have found a partner who was enthusiastic about the idea right from the start. The result: a complete success.

Quality standard

Our large circle of regular customers in domestic and foreign markets would be unthinkable without the high level of quality awareness that Hopf is known for. It runs consistently through all areas of our company.

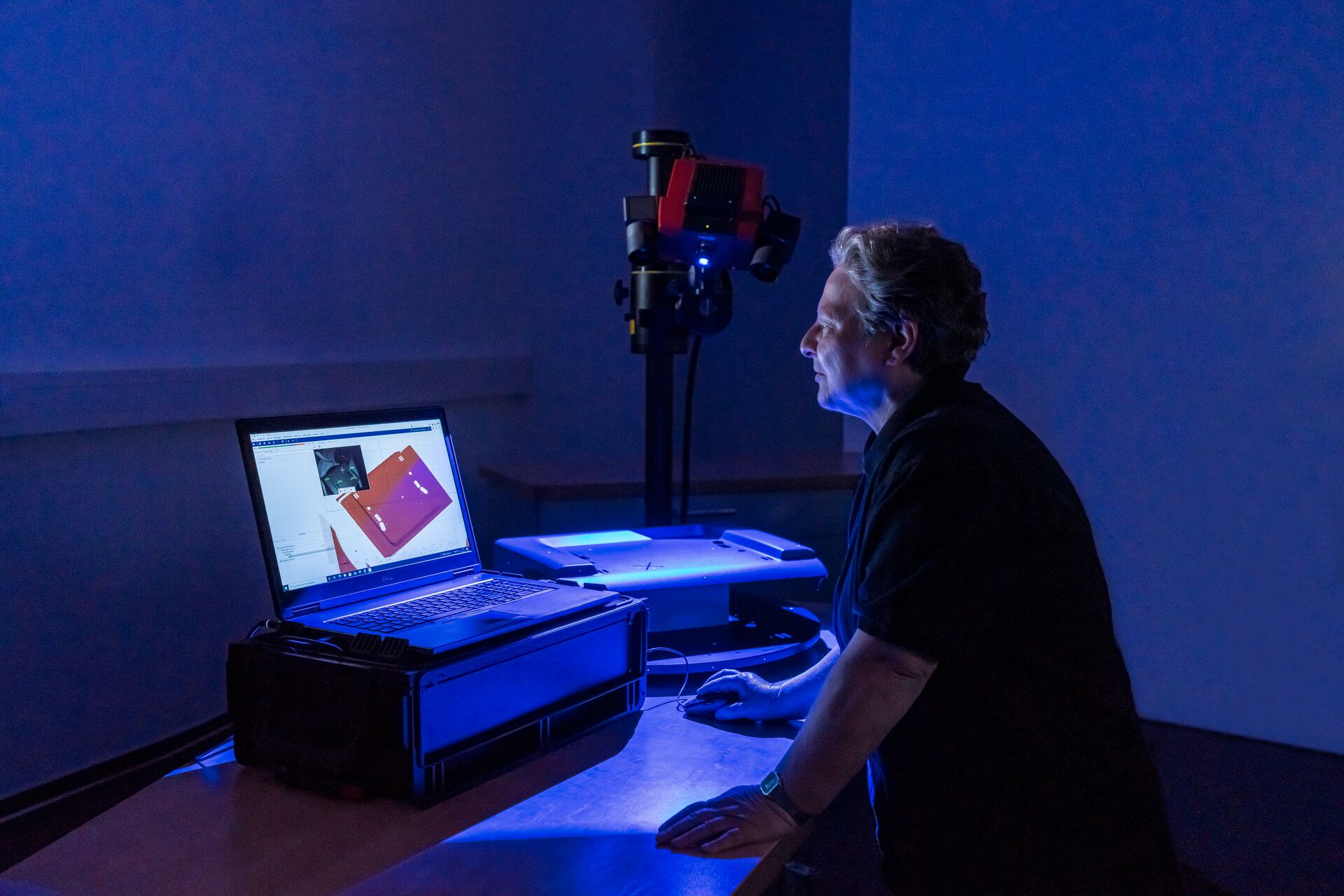

To ensure that your new component corresponds exactly to the specified dimensions, it undergoes a 3D measurement analysis as part of the final quality check. In addition to the surface deviation (between actual 3D coordinates and CAD data), the software provides information on shape and position tolerances, trimming or hole positions.

Our aim is to deliver each component in such a way that functional and optical requirements are met and it can be installed afterwards without stress.

Your contacts for all our services