Your project. Our passion. Joint success.

Passion for plastics technology has a long tradition at Hopf. As a family business, we have been manufacturing plastic products for a wide variety of industries since 1969. Our goal: to use our expertise to make your product concept even better – and to celebrate our joint success.

What drives us

Always striving for quality: Plastic products of the highest quality level. What we strive to be ourselves: a genuine source of ideas. Because we are passionate about what we do – ensuring that your product becomes even better when combined with our expertise.

From concept to product

Quality standard

Our large circle of regular customers in domestic and foreign markets would be unthinkable without the high level of quality awareness that Hopf is known for. It runs consistently through all areas of our company.

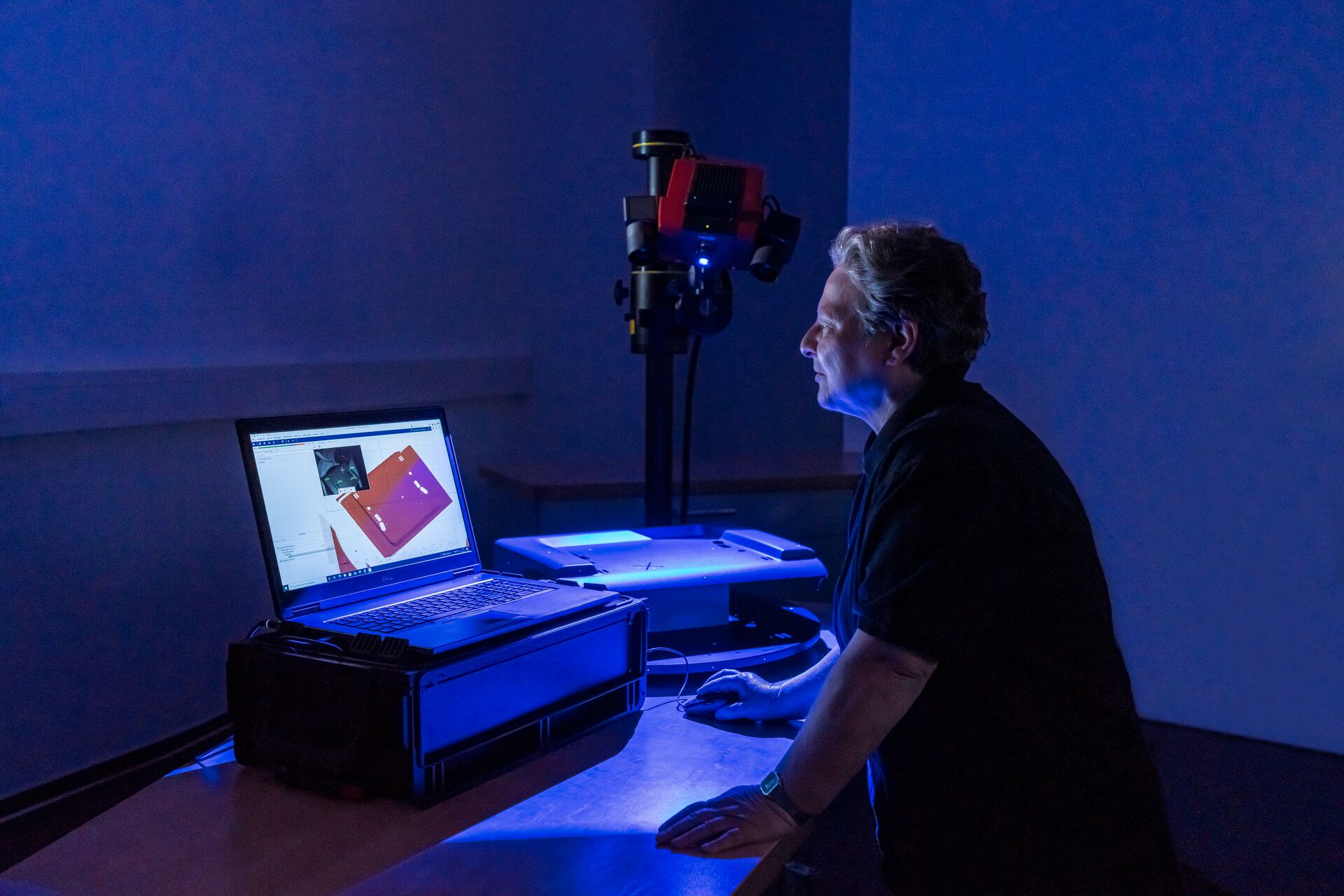

To ensure that your new component corresponds exactly to the specified dimensions, it undergoes a 3D measurement analysis as part of the final quality check. In addition to the surface deviation (between actual 3D coordinates and CAD data), the software provides information on shape and position tolerances, trimming or hole positions.

Our aim is to deliver each component in such a way that functional and optical requirements are met and it can be installed afterwards without stress.

Sustainability

As a family business, we feel a responsibility both to you as a customer and to the environment. In addition to our own solar system that has been reducing our CO2 emissions for many years, we consistently feed our plastic waste into an effective recycling process that means we are able to achieve almost 100% reusability. These initiatives mean we can not only offer you a more cost-effective material alternative, but also actively save resources.

And what is created when sustainability meets a wealth of ideas? Correct! Sustainable Hopf-brand products. After all, we don’t just make our customers’ concepts a reality, but our own as well.