How to make a wall box even better

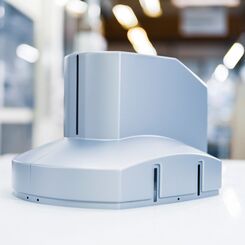

Making sustainable products even better – that’s what we at Hopf love. When this start-up company for electronic charging infrastructure approached us with its request, it quickly become clear that there was still room for optimisation. The product: a newly developed wall box – previously equipped with a standard injection moulded housing. Our task: to construct a new plastic housing for cladding and protection of the electronic components inside. We designed a thermoforming solution that adapts optimally to the interior peripherals. The result: an elegant look coupled with space savings thanks to a slimmer housing.

Other key customer requirements included: meeting a special fire protection class, protection against splash water, ease of assembly and, last but not least, sustainability of the material. We rely on our regenerated products made of ABS (acrylonitrile butadiene styrene) for this purpose. Thanks to a special recycling process, we have succeeded in reusing our sorted plastic waste as a material. This is our contribution to the conservation of resources, of which we are very proud. Perhaps this is also an option for your product? We are happy to advise.